Process & Pipeline Services

We have the people and equipment necessary to tackle any project regardless of size, in a timely manner that is efficient, cost effective, and safe.

Process & Pipeline Applications

Nitrogen Process Purging & Inerting

During facility maintenance turnarounds nitrogen is used during shutdown to purge dangerous gases or liquids from vessels, towers, and tanks, which leaves an inert atmosphere for safer maintenance.

Prior to plant start-up nitrogen is again used to remove oxygen from process systems reducing the potential of fire or explosion.

Accelerated Cool-Down

Once catalyst units are free of hydrocarbons, cold nitrogen at high flows accelerate the cooling of catalyst beds and vessel walls in a controlled manner thus saving valuable time during a facility outage or turnaround.

Nitrogen is also used to support catalyst removal after the catalyst beds have been cooled. A continuous stream of nitrogen keeps oxygen away from pyrophoric catalysts and residual hydrocarbons preventing heat ups and explosions.

Process Drying

The low moisture content (-60° C dew-point) of industrial grade nitrogen combined with heating capabilities make it an ideal medium to remove air and residual moisture from critical chemical process units.

Hot nitrogen is used for fast effective hydrocarbon stripping in fixed bed reactors and molecular sieve units prior to catalyst inspection or change-out.

Pneumatic Pressure Testing

Nitrogen or dry air is used instead of a liquid when the piping/vessel cannot support the liquid weight, or the piping/vessel cannot be dried and traces of the test liquid may result in contamination of the system after returning to service. A pneumatic test is inherently more dangerous than a hydrostatic test due to the higher energy content of a compressed gas.

Serious injury and/or property damage may occur due to a failure during a pneumatic test. Careful preplanning and thorough risk assessments are essential in assuring that a pneumatic pressure is completed successfully.

Pipeline Drying

A pipeline that is put into service dirty and wet is more susceptible to becoming corroded, eroded and having isolation valves that will not properly seal. This can lead to costs ranging from 5% to 10% more to operate in the intervening years due to poorer flow characteristics. There are a number of more reasons why this service line should be conducted but techniques will fall into two categories: those that address the prevention of hydrate formation, and those that physically remove all the water from the line.

Methanol and glycol are used to lower the hydrate formation temperature and are typically applied by running a pig train through the line at start-up. The basis of the air drying technique is to run a series of light (2 lb/ft³) polyurethane foam swabs through the line with very dry air (dew point of -68°C). The swabs initially absorb large quantities of water and ensure that water in the pipeline is continually spread out in a thin film, thus facilitating evaporation into the dry air stream.

Nitrogen Pipeline Purging & Displacement

Displacement pigs are inserted into pipelines and propelled by nitrogen gas to remove natural gas, crude oil, gasoline, diesel fuel, LPG and other explosive products leaving the pipeline in a clean, dry, and inert state.

Dry nitrogen is also ideal for removing water after hydro-testing to protect moisture sensitive products such as ethylene or chlorine from contamination.

Helium Leak Testing & Detection

To insure that facilities are safe for start-up, systems can be pressured up beforehand with nitrogen mixed with a small tracer gas component. Flanges, valves and seals within the system are exposed to specialized instruments that are sensitive to tracer gas to locate and quantify the leak rate.

Air Blowing

System Cleaning

The removal of construction debris and loose mill scale from plant piping systems is critical for proper operation. Systems placed into service without a thorough cleaning will soon be plagued with clogged intake screens, control valve trims or instruments and other costly problems.

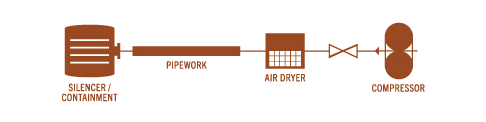

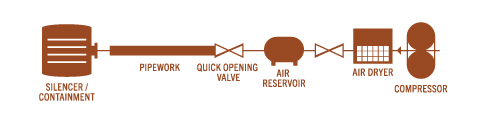

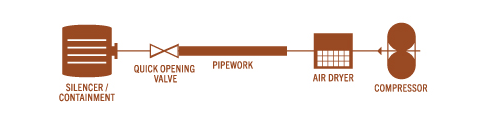

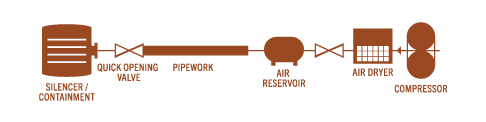

Continuous vs Rupture Cleaning Techniques

Air blow cleaning techniques utilize high-velocity air in either a continuous or intermittent operating mode to accomplish a thorough cleaning of pipework internal surfaces. These techniques can be broken up into continuous air blows and rupture air blows, where rupture air blows pressurize either the pipework or a temporary vessel installed upstream of the pipework.

CFR Determination

Copper Tip’s engineering group will determine the best technique to use by calculating the mass flow rate of the gas during the blow; this is called the Cleaning Force Ratio (CFR). The CFR compares the mass velocity head during the cleaning with that developed during operation at the designed maximum flow.

A CFR ratio greater than 1 ensures that the mass velocity during cleaning is greater than that developed during operating conditions; air blows designed will aim to achieve a minimum CFR of 1.25.

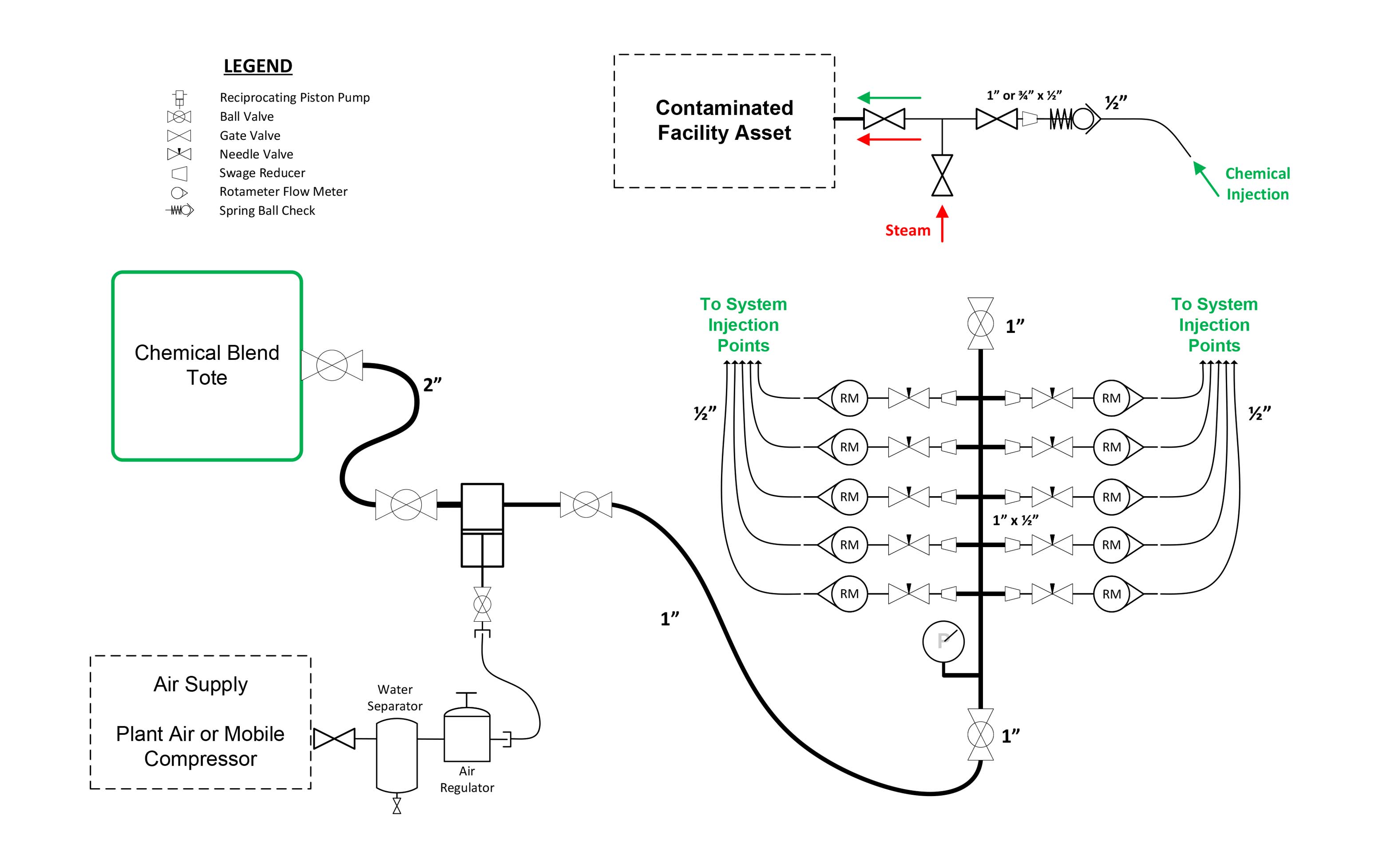

Vapour Phase Chemical Cleaning

Vapour Phase Cleaning (also known as degassing or decontamination) is one of the most efficient methods for cleaning facility piping and vessels when they are taken out of service for maintenance or layup. Steam is used to carry a potent cleaning chemistry throughout the vessel and piping system, breaking down and mobilizing any organic fouling.

This process significantly reduces the volume of waste generation when compared to a conventional chemical circulation cleaning, and shortens the time needed between the outage start and when the maintenance crews can begin.